A major concern of all countries to save the planet, decarbonization to mitigate the emission of greenhouse gases from oil exploration and production is the challenge of engineers and researchers of the 21st century who are looking to find innovative techniques capable of balancing the difficult equation between increasing energy demand due to industrialization and the democratization of mobility on the one hand and the vital need to preserve the environment.

Coming from powed drilling machines and ESP pumps, CO2 is considered by climatologists as the real disaster that threatens nature and humanity. Decarbonizing these means of production is no longer a luxury but an absolute necessity and UpStream decarbonization is part of this logic to limit their nuisance power, which worsens as energy demand increases.

Alerted by this global warming disaster, oil companies have made considerable efforts to decarbonize their oil and gas production processes, but there remains a huge component of the Upstream segment from diesel in operations in the middle of the desert and in the forests that hinder this decarbonization effort for a cleaner nature.

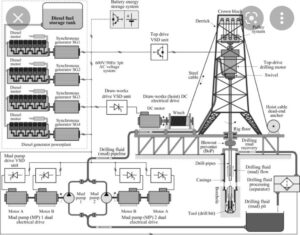

The scenario is to use hydrogen as a clean fuel for power generation machines. This is a new challenge that consists in reconciling energy production means with environmental requirements because with drilling rigs using 3 generators with an average of 2,000 KVa and 2,000 Liters of diesel per day or no less than 5 tons of CO2 daily as well as particles and nitrogen oxides. The challenge is to replace these traditional generators with electro-hydrogen units, such as EODev GEH developed by EODev (www.eo.dev) whose characteristics are:

- Modular power from 100 KVA to 2,000 KVA

- Zero emissions (0 C02, 0 CO, 0 HC, 0 NOx, 0 PM) produces pure water and filters ambient air

- Toyota fuel cell technology type “PEM” with an average efficiency of 50% coupled with a Litium battery for a stable and instantaneous power supply.

Considering the number of drilling rigs and ESP pumps in the world and their diesel operating needs, the calculation of CO2 emissions and their consequences on the climate are disastrous. As an indication, in Saudi Arabia, which has the largest oil fields, there are 239 RIGs that require 500,000 KVA and thousands of tons of diesel to operate them and the ambition to convert them to hydrogen would save so many polluting products.

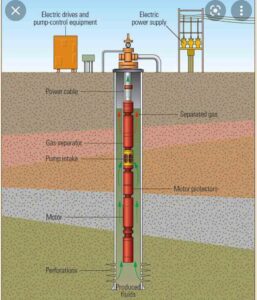

To further deviate the oil ecosystem, the same innovative process can be extended to ESP pumps that run on diesel and are massively used in oil fields, causing great damage to nature and human being.

For offshore drilling, the big surprise can come from there since a 1000 KVA H2 unit are under development, helped by the presence of water as a cooling system.

Replacing highly heated and polluting thermal machines with clean hydrogen processes is part of this scientific approach to decarbonization to promote Biofuels and achieve the climate objectives set by COPs 21 & and 26.

- Pictures Thanks to schlumberger and direct science.

Imed Derouiche /Energy Expert

Stéphane Jardin /CCO – EODev